The raw grain for this project design is hard wheat from Hubei Province, China. It contains 2.0% of impurities, 0.13% of gravels, and 4.2% of different grains. The normal grain cleaning process can meet the cleaning requirement.

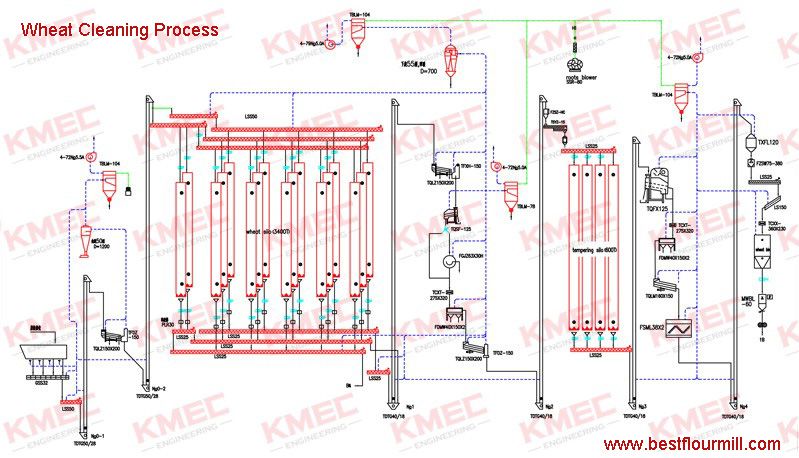

Specific procedure please see below:

Raw grain→ cylinder screen → measuring scale → dirty wheat bin → vibrating screen → destoner → classificator → magnetic separation → horizontal scourer → rotary sieve classifier → intensive dampener → conditioning bin → twice destoning → magnetic separation → vertical scourer → rotary sieve classifier → atomizing dampener → midbin → electronic scale

(If you want to see larger version of the above picture, please fill in the form at the end of this page.)

In the cleaning of grain, we obey the principle of easy to difficult, and big to small. This procedure aims at getting rid of big impurities mixed in wheat that are easy to be cleared away, and the strong winnowing can clear away large proportion of dust. As the big impurities mixed in the raw wheat grains from China are most of the time long and soft: if they are not cleared away fist, these impurities will block the pipes and the inlet and outlet of following processing equipments and weighing equipment; or they will twine round the main working parts of the equipments and influence the normal operation and production.

The preliminary cleaning process is not only good to the process effect of following procedures, but is also beneficial to improving sanitation.

If the raw wheat weighing is set before wheat enters workshop for cleaning, it can accurately reflect the processing amount of raw grain, which makes economic calculation much easier. However, when we consider the features of big impurities in raw wheat, if the wheat is not pre-cleaned and goes to the weighing equipment directly, it will affect the measuring accuracy and the safety of weighing equipment. More seriously, the impurities may make the weighing appliance unable to work normally.

Therefore, it is advised to weigh and calculate after preliminary cleaning; while the impurities that are sieved from preliminary cleaning per shift shall be weighed and recorded, and then calculated to raw grain, in order to correctly reflect raw wheat usage amount for calculating flour extraction rate.

The big and light impurities, and broken grains shall be get rid of by winnowing selection and screening. This process adopts the vibrating screen that has vertical suction air duct for cleaning. The equipment which combines winnowing and screening can realize the clearing of broken grains and different types of impurities with 1 set of machine and 1 procedure.

The vibrating screen has 2 layers of sieve: the first layer is used to remove big impurities, and the second layer can remove small impurities. The vertical suction air duct can wipe off light impurities: when the wind speed excesses light impurities floating velocity but under grain floating velocity, it can assure good result.

The screen size of rotary sieve classifier is different from vibrating screen, therefore it can remove the big, medium and small impurities that vibrating screen cannot clean.

The aim of de-stoning is to remove gravels in raw wheat. The de-stoning technology is generally designed after cleaning procedure, so that the impurities and different type grains can be removed in previous procedures, and the scalelike holes and sieving holes in de-stoning procedure will not be blocked in order to guarantee good de-stoning result.

Ever since the invention of commercial flour mill plant, de-stoning procedure has been the most important step in cleaning part, since it has great impact on following procedures as well as product quality. Traditional de-stoning method was to set a de-stoner after wheat cleaning process. But practice has proved that this method can hardly guarantee final flour quality, but it can even bring difficulty to operation. The reasons are: on one hand, raw wheat contains too many gravels, especially those similar to wheat grain size; on the other hand, the de-stoning machine has high operation requirements, for it is hard to control wind capacity and flow rate, but these are all determining factors in de-stoning effect.

The purpose of magnetic separation is to clear away the magnetic impurities in raw grain. This process shall be planned after preliminary cleaning, but before the equipments with strong friction and striking force. The magnetic separation is a necessary procedure before the wheat goes into scourer and clean wheat bin. It assures that no magnetic substances enter following flour milling process, since such substances not only affect processing effect, but also damage equipments. Therefore, it is a must to add magnetic separation before the equipments with high speed and the finished product packing.

The purpose of magnetic separation is to clear away the magnetic impurities in raw grain. This process shall be planned after preliminary cleaning, but before the equipments with strong friction and striking force. The magnetic separation is a necessary procedure before the wheat goes into scourer and clean wheat bin. It assures that no magnetic substances enter following flour milling process, since such substances not only affect processing effect, but also damage equipments. Therefore, it is a must to add magnetic separation before the equipments with high speed and the finished product packing.

This magnetic separation step utilizes the theory that its main work element magnet can attract the magnetic substances and leave non-magnetic wheat, in order to achieve the purpose of efficiently separating magnetic substance and grain.

In wheat flour milling technology, purifying means use special equipment to separate different grain particles (like barley, oats or buckwheat) or broken wheat from complete wheat grains. It is one of the critical procedures in wheat cleaning process, since different kinds of grains will influence wheat flour quality and color.

Wheat surface threshing is designed to: 1. get rid of the dirt on wheat kernel surface; 2. remove the parts that have been eaten by worm or that is mildewed. The threshing forms can be divided into heavy threshing and light threshing: heavy threshing refers to the surface cleaning after tempering; light threshing is the surface cleaning before tempering. The threshing methods can be divided into wet threshing and dry threshing. The light threshing utilizes horizontal wheat thresher, while heavy threshing utilizes vertical wheat thresher.

Working theory of thresher: wheat and impurities are different in the structure and strength. With the help of rotating plate and woven mesh that has proper size holes on the surface, when the material group goes into the mesh hole, it is stroked by the plate; impurities are broken and go through the holes, so as to achieve the purpose of removing impurity. The screening after threshing is to separate threshed impurities and wheat.

The purposes of wheat moisture adjustment are: 1. reduce the intensity of endosperm and save grinding power; 2. Increase cortex tenacity and maintain complete bran; 3. reduce the binding force between the cortex and endosperm, which is good to scrape the endosperm from cortex; 4. provide the best grinding moisture content; 5. increase the nutrition value of endosperm. Wheat moisture adjustment can be finished in one time, or in two or three times, but generally it is conducted after dirty wheat cleaning.

The flour milling plant we designed this time utilizes hard wheat from Hunan, China, whose best grinding water content is 15.5 ~ 17.5%, the first time tempering time is 24 ~ 32H, second time dampening time is 45 ~ 60min,while third time dampening is 30 ~ 45min. Commonly used water equipments are water mixer, water spraying machine and automatic water machine.

In this design, the first time wheat tempering adopts intensive dampener, which is a continuous high efficiency water equipment; it can add a proper amount of water into wheat, and the fully mixing of auger mixer can make water evenly distributed in every grain of wheat. The water spray machine is used for second time watering, and the dampening quantity is 0.1 ~ 0.5%.

Under the wheat tempering bin, there is added an auger device for delivery. The working principle of the screw conveyor: the rotating spiral blade push the material to screw conveyor, while the force that forbids the material to rotate with the spiral conveyor leaf is the material’s own weight and the resistance friction between the screw conveyor shell and the material.