Corn Flour Mill Plant Cost and Budget Analysis

Investing in a corn mill requires a well-structured financial plan. Understanding the corn flour mill plant budget is critical for project feasibility and return on investment. Typically, the budget consists of three main categories: fixed investment, operating costs, and installation expenses. Fixed investment covers machinery, land, and buildings, usually accounting for 65-70% of total capital expenditure (CAPEX). Operating costs, or OPEX, include labor, utilities, maintenance, and raw materials, often representing 25-30% of annual expenditure.

Production capacity significantly influences the overall investment. For instance, a plant with a capacity of 20 tons per hour (TPH) generally requires $3.5–4 million USD, while a 50 TPH facility can reach $7–8 million USD. Automation level is another key parameter: semi-automatic lines reduce initial CAPEX by 15% but increase OPEX by 10% due to higher labor involvement. Conversely, fully automated lines elevate CAPEX by 20–25% but cut OPEX by 12–15% annually.

Capital expenditure vs operational expenditure balance is essential for long-term profitability. A strategic approach involves forecasting 10-year cash flows, including equipment depreciation, energy cost escalation, and maintenance cycles. Efficient financial modeling can prevent budget overruns exceeding 8–10% of initial estimates.

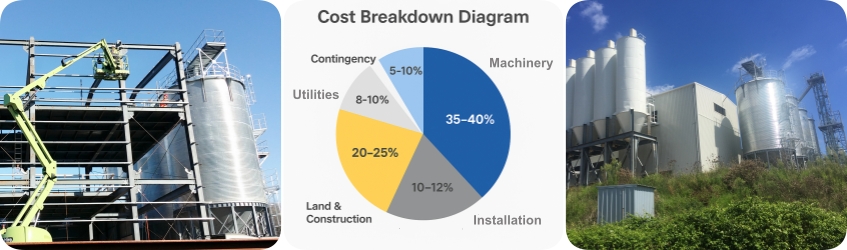

| Component | Approx. Share (%) | Key Considerations |

|---|---|---|

| Land & Civil Construction | 20–25% | Site selection, foundation strength, local construction rates |

| Major Corn Mill Machinery | 35–40% | Milling, cleaning, degerming, packaging equipment |

| Installation & Commissioning | 10–12% | Labor, scaffolding, electrical wiring, conveyor integration |

| Utilities & Energy Setup | 8–10% | Boilers, motors, transformers, energy efficiency measures |

| Contingency & Miscellaneous | 5–10% | Unexpected costs, project delays |

Corn Flour Mill Plant Budget and Cost from Land to Profitable Factory

Partner with our experts to optimize your corn flour mill investment plan and maximize ROI with precision cost analysis.

Key Equipment in Industrial Corn Processing Plant

Selecting the right machinery directly influences the corn flour mill plant budget. Key equipment includes cleaners, degerminators, roller mills, sifters, and packaging lines. A standard 30 TPH plant typically requires $1.8–2.2 million USD for core machinery. Installation and commissioning can add another 8–10% of total equipment cost.

Optimized equipment layout reduces material handling distances by 15–20%, lowering conveyor installation expenses. Proper sequencing ensures that commissioning time does not exceed 6 weeks, avoiding labor and downtime overrun.

Contact us to review your corn mill equipment selection and installation cost optimization strategies.

Energy consumption accounts for 12–15% of annual OPEX in most corn mills. Implementing high-efficiency motors and smart control systems like MES can reduce energy usage by 10–15 kWh per ton of flour. Advanced degermination techniques and optimized milling stages minimize waste and maintenance costs. For instance, configuring 2-stage roller milling with NIR (Near-Infrared Reflectance) sensors can improve yield by 3–5% while reducing cleaning downtime by 20%.

Explore energy-efficient corn milling process design options with our engineering consultants to lower your operational costs.

Selecting the appropriate financing model impacts overall investment efficiency. EPC contracts consolidate design, procurement, and construction, often saving 5–8% of total project costs. Staged investment or leasing allows for phased deployment and cash flow flexibility.

Cost optimization strategies include local procurement of auxiliary equipment (saving up to 12%), modular construction, and phased commissioning. These approaches reduce upfront CAPEX while maintaining project scalability.

Get in touch with our finance and project engineering teams to create a cost-effective corn flour mill investment plan tailored to your production needs.

A thorough understanding of corn mill construction budgets ensures that every investment decision is informed by data, technical feasibility, and operational efficiency. From initial CAPEX to long-term OPEX, well-planned budgeting is the foundation for a profitable corn flour mill project. Boldly evaluating equipment, energy, and financing strategies allows investors to maximize returns while controlling costs.