Small Corn Mill Setup Guide for Startups

The global corn mill industry is expanding steadily, with an estimated annual growth rate of 4.8% between 2024 and 2030. Demand for processed corn products—such as corn flour, grits, and starch—continues to rise, particularly in developing regions of Africa, Southeast Asia, and Latin America. This creates strong investment potential for small corn mill setup projects targeting localized processing.

Establishing a small corn mill allows investors to capture niche regional markets where transportation costs and import tariffs make imported flour less competitive. Entry barriers are relatively low: the initial investment typically ranges from USD 80,000 to 150,000, depending on capacity and automation level.

Additionally, sustainability goals are reshaping the corn milling business. Energy-efficient systems and waste recovery technology can reduce power consumption by 10–15% per ton of product. Small mills adopting solar-driven or hybrid power setups are increasingly supported by local governments through green energy subsidies.

10TPD Small Maize Milling Machine for Sale

Explore high-return opportunities in the emerging mini corn processing industry — connect with our project engineers to design your optimal small corn mill investment plan.

Efficiently building a small corn mill setup requires a structured approach that combines feasibility analysis, optimized factory layout, appropriate corn mill machine configuration, and smart automation solutions.

Before procurement or construction, a feasibility study evaluates market potential, expected capacity (commonly 1–5 TPH), raw material availability, and ROI projections. For example, a plant producing 2 tons/hour can yield about 4,000 tons annually, assuming 16 operating hours per day and 250 working days per year. A well-prepared feasibility study helps investors identify a 15–20% margin improvement through proper cost modeling.

Factory siting should ensure easy access to corn supply, water, and electricity. The ideal plant size for a 2-TPH facility is around 1,200–1,500 m², including storage, processing, and packaging zones. Proper corn milling plant design ensures efficient material flow—raw corn moves linearly through cleaning, conditioning, grinding, sieving, and final packaging.

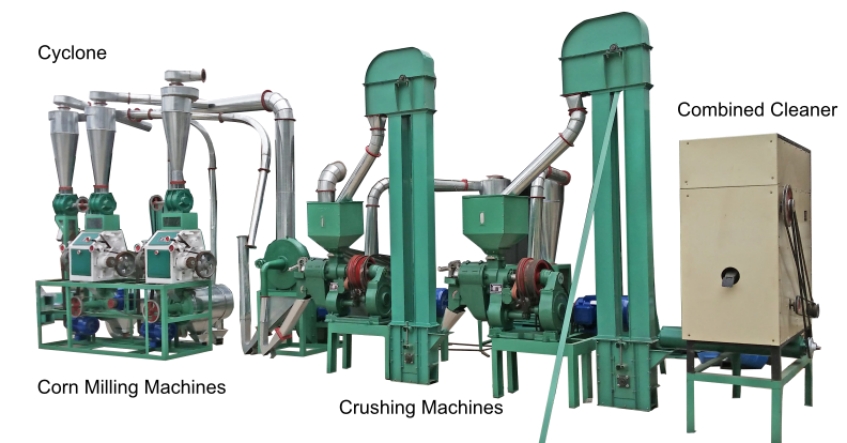

A complete corn mill equipment configuration typically includes four major systems: cleaning, grinding, sieving, and packaging.

| Process Section | Key Equipment | Typical Capacity | Energy Consumption |

|---|---|---|---|

| Cleaning | Vibrating separator, destoner, magnetic separator | 2–5 TPH | 3–5 kWh/ton |

| Grinding | Roller mill or hammer mill | 1–3 TPH | 8–10 kWh/ton |

| Sieving | Plansifter, purifier | 1–4 TPH | 2–3 kWh/ton |

| Packaging | Auto-weighing and sealing system | 10–20 bags/min | 1 kWh/ton |

A Simple Corn Flour Production Line Equipment List: Cleaning, Crushing, Grinding Machines

Modern control panels and smart data analytics allow operators to monitor yield and energy usage in real time. Integrating NIR (Near-Infrared Reflectance) technology in quality inspection ensures moisture accuracy within ±0.2%, enhancing flour uniformity and reducing rejection rates.

Smart automation systems make small mills highly competitive. For instance, an automated 3-TPH corn mill consumes only 12 kWh per ton—20% lower than manual systems—and cuts labor requirements from 8 workers per shift to 4. These metrics significantly impact profitability and long-term sustainability.

Proper engineering integration is the backbone of every profitable corn milling project. Get your customized plant design and process optimization proposal from our industrial engineering experts today.

A small corn mill investment cost involves three major categories: equipment purchase (40–50%), civil construction (20–25%), and installation and utilities (15–20%). For a 2-TPH plant, the total investment typically ranges from USD 120,000 to 180,000.

Operating costs—such as power (averaging 10 kWh per ton), labor, and maintenance—can represent 60–70% of total production costs. To improve energy efficiency, investors can adopt inverter-driven motors and efficient dust collection systems that save up to 12% of power.

ROI (Return on Investment) for a small scale corn mill project generally reaches 18–25% within 2–3 years if local raw corn is available at stable prices.

Boost your project's profitability and operational efficiency — consult our engineering team for tailored cost-control strategies.

Effective small corn mill operation requires consistent raw material quality, preventive maintenance schedules, and tight process monitoring. Daily cleaning reduces downtime by 5–7 hours monthly, while maintaining sieve mesh integrity improves yield by 2–3%.

Scaling up from a small to a medium corn flour production line involves modular expansion—adding additional grinders or sifting units while retaining the same control system infrastructure. This approach minimizes downtime during upgrade phases.

Supply chain optimization is equally important: securing reliable corn suppliers within a 100 km radius can reduce logistics expenses by 15%.

Partner with us to transform your small corn mill into a scalable, high-efficiency production facility with global competitiveness.

At every stage—from feasibility study to full-scale operation—a corn mill investment provides sustainable and profitable growth potential. With the right small corn mill setup, investors can achieve efficient production, fast market response, and strong ROI in competitive global markets.